Thermal Energy Storage: A Game-Changer for Sustainable Cooling in Energy-Intensive Buildings.

- Operations-TEAM | Klimaire-HVAC

- Sep 1, 2023

- 11 min read

Explore the untapped potential of Thermal Energy Storage (TES) in revolutionizing cooling systems for energy-intensive buildings. As an emerging technology rooted in established principles, TES promises to slash air conditioning costs by up to 50%, while paving the way for next-generation green buildings. This technical article targets construction industry professionals across North and South America, providing an in-depth look into how TES systems can be a cornerstone for sustainable, high-performance buildings.

Sustainable Building Solution.

The air conditioning of commercial buildings, particularly during the sweltering summer months, is the primary driver of electrical peak demand. This necessitates electric suppliers to deploy additional, often less efficient, generating equipment to cater to the surge. Commercial enterprises, responsible for substantial air conditioning loads, are penalized with elevated “On Peak” energy costs either via increased energy charges or "Demand Charges," often calculated based on peak consumption over a specified timeframe. Such operational inefficiencies not only contribute to increased operational expenditures but also exacerbate the environmental burden through greater carbon emissions.

In this scenario, Thermal Energy Storage (TES) emerges as a transformative solution, promising not just significant economic savings but also a more sustainable approach to building management. TES systems allow for off-peak energy consumption, resulting in reduced demand during peak hours, smaller carbon footprints, and less strain on electrical grids. Designed for the construction industry professionals operating in the Americas, this technical article will delve into how TES can be an instrumental technology in achieving green, high-performance, or net-zero building status while mitigating the energy and environmental challenges associated with conventional cooling systems.

What is an Ice Bank Cool Storage System?

An Ice Bank Cool Storage System, commonly referred to as Thermal Energy Storage (TES), is a cutting-edge energy management technology specifically designed to shift electrical load from high-demand, peak periods to low-demand, off-peak hours. This system optimizes the cooling capabilities of commercial and industrial buildings, offering significant reductions in both energy consumption (measured in kilowatt-hours or kWh) and demand charges.

How Does Ice Bank System Work?

The Ice Bank Cool Storage System offers a multifaceted approach to sustainability, balancing economic and environmental objectives effectively. Its application is instrumental for any energy-intensive building aiming for green or net-zero status:

Off-Peak Energy Utilization: At the core of the Ice Bank System is a standard chiller, which operates predominantly during nighttime off-peak hours when the building’s electrical load is at a minimum. During these hours, electric supplier rates are substantially lower because of under-utilized generating capacity. The chiller produces solid ice, which is then stored in modular ice tanks.

On-Peak Load Shifting: The stored ice is used the following day to meet the building's cooling requirements, thus permitting the chiller to be either downsized or completely turned off during peak hours. This dramatically reduces the instantaneous demand for electricity during high-demand periods, diminishing both energy costs and demand charges.

Reduced Operating Costs: By shifting the energy load to off-peak hours, Ice Bank Systems offer substantial savings in operating costs. This enhances a user’s negotiation power in deregulated energy markets by increasing the building’s "Load Factor" (Average Load ÷ Peak Demand).

Capital Expenditure Savings: In new installations, specifying half-size chillers that operate almost continuously can result in capital savings compared to installing full-size chillers that operate for limited hours. In retrofit applications, the Ice Bank system can often provide additional cooling without requiring an increase in chiller capacity.

Improved Energy Efficiency: Operating chillers at near full load continuously enhances the system's energy efficiency, as most chillers are less efficient when operated at part-load.

Lower Greenhouse Gas Emissions: By reducing the need for peaker plants during high-demand periods, the system indirectly contributes to lower greenhouse gas emissions.

Grid Stability: The off-peak energy storage improves grid stability and allows energy suppliers to manage their resources more efficiently, preventing the capital outlays required for new generating plants.

Versatility in Installation: Ice Bank tanks are modular and can be easily accommodated in different configurations, either indoors or outdoors, providing flexibility in building design.

Cool Storage Global Adoption: With over 6,000 installations worldwide, the technology is mature and proven, providing confidence in its long-term viability and performance.

Conceptual Analysis of Cool Storage Systems.

In traditional air conditioning (AC) system, cooling loads are quantified using units termed "Tons of Refrigeration" or equivalently in kilowatts (kW). However, Thermal Energy Storage (TES) systems like Cool Storage employ a different metric: "Ton-Hours" or kilowatt-hours (kW-h). In a hypothetical scenario represented by Figure 1, the cooling load is 100 Tons sustained over a duration of 10 hours, equating to a cumulative load of 1000 Ton-hours. Each block in the diagram signifies 10 Ton-hours.

It is crucial to note that building AC systems seldom operate at full capacity throughout the entire daily cooling cycle. Peak loads usually materialize between 1400 and 1600 hours, coinciding with maximum ambient temperatures. Figure 2 delineates a typical diurnal cooling load profile under design conditions. Here, a 100-Ton chiller operates at full capacity merely for a two-hour window; lesser capacity suffices for the remaining operational period. When one quantifies the shaded blocks in the figure, the sum amounts to 750, each block symbolizing 10 Ton-hours.

The "Diversity Factor" is formally defined as the ratio of the actual cooling load to the maximal prospective chiller output. Mathematically, Diversity Factor (%) = (Actual Ton-hours / Total Potential Ton-hours) = (750 / 1000). Consequently, the chiller in this example exhibits a Diversity Factor of 75%. The system is engineered to supply 1000 Ton-hours while the actual requirement is 750 Ton-hours. A low Diversity Factor is an indicator of suboptimal system cost-effectiveness. The potential for economic advantage through the implementation of a Cool Storage system is directly proportional to the inverse of the Diversity Factor.

To ascertain the building's mean load throughout the cooling cycle, one divides the total Ton-hours by the chiller's operational hours. If the cooling load were to be shifted to off-peak periods or equilibrated to this average, it would necessitate lesser chiller capacity, thereby achieving 100% diversity and enhancing cost-efficiency.

Full Storage vs. Partial Storage: A Technical Perspective.

Cool Storage systems offer a range of control methodologies to capitalize on their inherent advantages; however, there are two foundational strategies - Full Storage and Partial Storage - that serve as the cornerstones for system design. The specific control mechanisms chosen often depend on the electricity rate structure.

In scenarios where electricity rates substantiate the total transference of air-conditioning load to off-peak periods, a Full Storage system can be deployed, typically leveraging existing chiller infrastructure, especially in retrofit applications. In this configuration, shown in Figure 3, the chiller is operational only during off-peak hours to accumulate ice in Ice Bank reservoirs. The thermal energy, stored at a temperature of 32°F (0°C), is subsequently harnessed to fulfill a 750 ton-hour cooling load during peak times. The mean load is thereby diminished to 53.6 tons (750 ton-hours ÷ 14 hours), eliminating the necessity for daytime chiller operations and consequently minimizing demand charges.

Conversely, Partial Storage systems are frequently the most pragmatic and economically viable solutions for new constructions. Under this strategy, depicted by the dotted line in Figure 4, a downsized chiller operates throughout the 24-hour cycle. It accrues ice in storage tanks during nocturnal off-peak hours and collaboratively utilizes this stored thermal energy for daytime cooling. By stretching the operational hours from 14 to 24, the average load plummets to 31.25 tons (750 ton-hours ÷ 24 hours), enabling considerable reductions in demand charges and often facilitating chiller downsizing by 50–60% or more.

It's noteworthy that the 24-hour mean load is 31.25 tons, but the chiller's actual capacity oscillates - being marginally elevated during daylight and reduced at night. This is attributable to a 30-35% derated chiller capacity for ice formation, discussed in the succeeding section, which should not be conflated with an efficiency de-rating.

Ice Bank Thermal Storage System.

The core component of the Ice Bank Cool Storage System is a modular, thermally-insulated polyethylene reservoir incorporating a spiral-wound plastic tube heat exchanger immersed in water. The tank dimensions vary, offering storage capacities from 45 to in excess of 500 ton-hours. During nocturnal, off-peak hours, a chiller cools a 25% ethylene glycol-water mixture, which is then circulated through the heat exchanger. This process leads to thermal energy extraction until approximately 95% of the aqueous volume within the reservoir attains a solid, frozen state (Figure 5). Notably, the freezing process is designed such that water is not encapsulated by ice, thus ensuring laminar flow and averting structural damage to the reservoir.

In the Partial Storage system, exemplified in Figures 6 and 7, an ethylene glycol-water mixture undergoes a nocturnal cooling cycle via the chiller and the integral heat exchanger in the storage tank, circumventing the air handler coil. The cryogenic medium attains a temperature of 25°F, facilitating the phase transition of adjacent water into ice within the heat exchanger.

Subsequently, during diurnal operations, the thermal energy stored as ice reduces the glycol-water solution's temperature from an inlet value of 52°F to an exit value of 34°F. A thermally-actuated control valve, set at 44°F and positioned in a bypass conduit parallel to the ice storage tank, modulates the flow to amalgamate the 52°F and 34°F streams, achieving a homogenized fluid temperature of 44°F. This conditioned medium interacts thermodynamically with the air across the air-handler coil, typically altering the air temperature from an inlet condition of 75°F to an outlet condition of 55°F. The thermal fluid is then reconditioned in the chiller from 60°F to 52°F before re-entering the cycle.

It is pertinent to note that, during the ice-generation phase, the chiller operates at a reduced effective capacity, necessitating cryogenic fluid temperatures of 25°F as opposed to the standard 44°F or 45°F. This results in a nominal de-rating of the chiller’s capacity by approximately 30 to 35 percent. However, compressor performance metrics remain quasi-stable due to the favorable condensing temperatures associated with nocturnal operations.

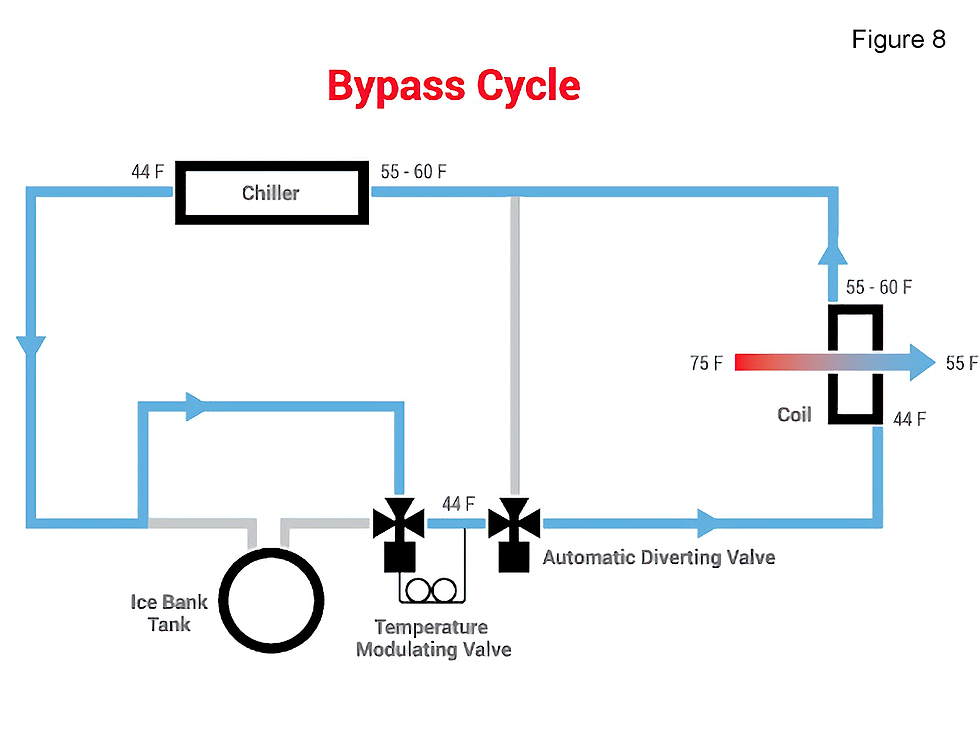

The thermally-actuated valve in the bypass conduit affords an unbounded capacity modulation mechanism. During temperate climatic conditions in transitional seasons, the chiller alone may suffice in meeting the building’s entire thermal load. Under such scenarios, the glycol-water medium is exclusively directed through the bypass loop, as depicted in Figure 8.

The ethylene glycol employed is an industrial-grade coolant, formulated specifically for low viscosity and optimized thermal conductivity. Its inclusion of a multi-component corrosion inhibition system renders it compatible with conventional system components, such as pumps, seals, and air handler coils. Adjustments to the thermal fluid's supply temperature may be necessitated, typically requiring a decrement of 1-2°F, to offset the minor disparity in heat transfer coefficients between the glycol-water mixture and pure water.

How Thermal Energy Storage Optimizes Cost-Efficiency and Sustainability.

Peak-Shaving for Economical Operation: Utilizing the chiller during off-peak hours can yield considerable cost savings, up to 90% in some cases, thanks to lower energy rates offered to incentivize load shifting (Figure 9). This operational strategy elevates your facility to a 'Preferred Power User' making you eligible for special rate negotiations.

Full-Load Efficiency: Traditional air conditioning systems operate at peak efficiency less than a quarter of the time due to intermittent cycling. The Ice Bank System, however, allows the chiller to run continuously at or near full-load, circumventing the inefficiencies of part-load operation (Figure 9).

Optimal Nighttime Operation: Air-cooled chillers exhibit enhanced performance during the cooler nighttime hours. Running the system at night with reduced condensing temperatures can improve energy efficiency by 2 to 8% compared to day-time operations (Figure 10).

Cold Air Distribution for Cost-Savings: Deploying 44°F air instead of the typical 55°F air via the Ice Bank System leads to substantial initial and ongoing savings. The lowered airflow requirements mean reductions of 20% to 40% in the cost and size of air handlers, motors, ducts, and pumps. Moreover, this colder air promotes comfort at energy-efficient thermostat settings. EPRI studies indicate that such a system can lower overall HVAC operating costs by 20% to 60%.

Quick Deployment and Minimal Upkeep: Ice Bank tanks are modular, easy-to-install units that come with a 10-year limited warranty. They offer flexibility in placement, indoors, outdoors, or even in stacked configurations, and require minimal maintenance due to their non-corrosive, static components.

Environmental and Supplier Benefits.

The Ice Bank system offers dual advantages: It is beneficial for both electrical suppliers and end-users. Operating off-peak significantly lowers the heat rate (fuel BTUs per kWh), translating to up to 30% less fossil fuel consumption (CEC report). This results in reduced greenhouse gas emissions, contributing positively to environmental stewardship.

By investing in thermal energy storage like the Ice Bank System, businesses not only stand to substantially reduce operational costs but also significantly contribute to environmental sustainability.

Return on Investment Analysis.

Facility and Rate Description Assumptions.

400-ton peak cooling load

10-hour cooling day

75% diversity factor

$13.00/kW/month utility demand charge

7-month cooling season.

Cost Breakdown.

Conventional System: Two 240-ton air-cooled chillers are installed to provide a safety factor and redundancy.

(2) 240-ton air-cooled chiller: $480,000*

Air distribution system: $240,000

Total installed cost: $720,000

(*) The $1,000/ton for air-cooled chillers includes all accessories such as pumps, piping, controls, etc.

Right-Sized Partial Storage System: Utilizes two 160-ton air-cooled chillers and stored cooling.

(2) 160-ton air-cooled chiller: $320,000*

Ice bank cool storage system: $210,000**

Air distribution system: $240,000

Total installed cost: $770,000

(**) The $150/ton-hour for the ice tank installation is outdoors on a pad, with glycol, piping, controls, etc.

Initial Investment Differential:

Total Differential: $50,000

ROI Calculation.

Annual Savings from Demand Charges:

(400-160) tons x 1.2 kW/ton x 7-months x $13 kW = $26,208

Payback Period:

$50,000 / $26,208 = 1.9 years

With a payback period of under 2 years, the Right-Sized Partial Storage System presents a compelling case for investment, offering not just energy savings but also operational flexibility and redundancy.

Carbon Footprint Reduction Analysis.

By reducing the peak demand from 400 tons to 160 tons, there is less strain on the electric grid, which often relies on less efficient, carbon-intensive peaker plants to meet high demand levels.

Carbon Emission Savings.

Reduced Peak Demand:

240 tons x 1.2 kW/ton = 288 kW

Emission Factor for electricity (average in the U.S.):

0.4 kg CO2/kWh

Carbon Emission Savings per hour:

288 kW x 0.4 kg CO2/kWh = 115.2 kg CO2

Carbon Emission Savings for 7-month cooling season:

115.2 kg CO2/hour x 10 hours/day x 7 months = 80,640 kg CO2

Approx. 81 metric tons

Additional Benefits:

By allowing for off-peak energy storage, the system also encourages the use of renewable energy sources, which often generate power at non-peak times.

Conclusions.

Thermal Energy Storage, particularly Right-Sized Partial Storage Systems, emerges as a Game-Changer for Energy-Intensive Commercial Buildings. This technology is not just a fiscally responsible choice, with a rapid payback period of under two years, but it also serves as a cornerstone in the quest for sustainability. The system provides significant carbon footprint reduction, which aligns perfectly with contemporary ESG compliance requirements.

By shifting electricity usage to off-peak hours, it effectively alleviates the strain on the grid while simultaneously lowering demand charges. This positions your building as an attractive customer for energy suppliers, potentially opening doors for beneficial rate negotiations. The reduced energy consumption and lower greenhouse gas emissions directly contribute to achieving green building status, making your property more marketable to environmentally-conscious tenants and partners.

In summary, thermal energy storage isn't just an emerging technology; it's a forward-thinking, smart investment for building owners.

Recommendations.

Conduct a Feasibility Study: Before diving into the installation, consult with energy engineers to evaluate the specific needs and constraints of your building. This ensures that the technology fits your operational requirements and sustainability objectives.

Right-Size Your Chillers: Opt for partial storage strategies that allow you to "right-size" your chillers. This approach not only minimizes initial capital investment but maximizes operational savings and efficiency.

Negotiate Energy Rates: The technology significantly improves your building's "Load Factor," making you an attractive customer to energy suppliers. Use this as a negotiation lever to secure more favorable energy rates.

Pay Attention to ROI and Payback Period: Based on current cost structures, the payback period is remarkably short, typically under two years. Consider this when planning your budget and sustainability milestones.

Plan for Growth and Scalability: As your building scales, the modular nature of thermal energy storage allows for easy expansion, providing a future-proof solution to energy management.

Leverage Sustainability for Marketing: Once installed, use your green building status to appeal to eco-conscious tenants and investors. This could translate to higher rental rates and increased property value.

Regular Maintenance: Like any mechanical system, thermal energy storage requires regular upkeep. Factor in maintenance costs while calculating ROI, and establish a robust maintenance schedule post-installation.

Consult Incentive Programs: Some regions offer financial incentives for green initiatives. Research and apply for these as they can substantially offset initial installation costs.

Legal Compliance: Ensure the technology meets all local and federal regulations, including those related to environmental protection and building codes, to avoid potential penalties or legal challenges.

Engage Stakeholders: Keeping shareholders and building occupants informed and engaged in the sustainability process can ease the transition and generate internal advocates for your green initiatives.

In closing, for Energy-Intensive Building owners aiming for sustainability, Thermal Energy Storage isn't just an option, it's a strategic imperative that promises substantial operational savings and a decisive step towards a greener future.

.png)